|

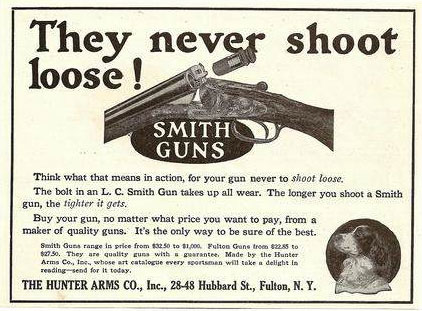

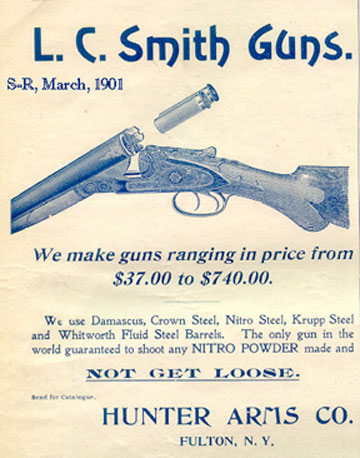

Illustrations from early 1900s Hunter Arms Co. catalogs show the Smith bolting mechanism with the claim that "SMITH GUNS NEVER SHOOT LOOSE"

"You will note by the cut that the bolt is built on a bevel; that it goes from one side of the frame entirely through the extension and into the other side, at the same time bolting over the end of the extension rib. The consequence is that the bevel of the bolt takes up all wear automatically and makes good our guarantee that the longer you shoot a Smith Gun the tighter it really gets."

So what is the basis behind this claim?

In 1921, Charles Askins wrote in The American Shotgun "It remained for America to have

the final word in bolting mechanisms. Lug bolts located on or as part of the barrels were in the

wrong place. The hinge-joint of the barrels acts as a fulcrum of a lever, upon which, the barrels

rest and pry at the bolts. It takes three times as much strength in bolts, to withstand the pressure

if they are placed an inch from the joint, as it would should the fastening be accomplished three

inches further away. Alex Brown moved his locking bolts from the lug and placed them in the

extension rib, which is undoubtedly the right position for them mechanically. Throughout the world

no other locking devise should be used on a shotgun save the rotary bolt."

The whole world had not taken Askins’ advice at that point in time, but some form of

primary or secondary top fastening system was used by Westley Richards, Greener, Rigby, and Beesley

in England, Merkel and most German-Austrian makers, the Manufrance Ideal, and in the U.S. by L.C. Smith,

Parker, D.M Lefever, William Baker designed Ithaca and later models, Baker and Hollenbeck designed

Baker Gun & Forging guns, Remington 1893 and 1894, and A.H. Fox.

William Wellington Greener in The Gun and Its Development 1907 provides an historical

perspective on bolting mechanisms.

"Top Lever Actions" are reviewed starting here in this 1907 book.

p. 145 THE WESTLEY RICHARDS' BREECH- LOADER.

"This gun is one of the first, if not the first, of the top breech-bolt mechanisms,

and was patented in 1862. In addition to the lump underneath the barrels, upon which they turn, here is a lump projecting from the breech ends at the top of the

barrels. This lump is of dovetail shape and has a hook; the projection fits into a

correspondingly shaped slot in the top of the standing breech, and is secured there

by a holding-down bolt sliding to and fro in the line of the barrels. This bolt is

pushed forward by a spring behind it, and is withdrawn by pressing the lever lying

between the hammers to the right. The object of this particular arrangement is

to prevent the standing breech from springing back at the moment of firing, and

was undoubtedly a step in the right direction. In 1865 the author invented a top

cross-bolt, which passed through an extension of the top rib, thus wedging the

barrels to the standing breech."

Back to Top

Chapter 15 of Shotgun Technicana by Michael McIntosh and David Trevallion discusses ‘Top Fasteners’ and specifically the Alexander Brown patent, and the almost identical Ansley Fox patent.

"The most basic principle in fastening any hinge is that the farther the fastener is from the hinge itself, the greater the mechanical advantage. That’s why door latches are placed where they are. In a gun, the action bar and breech face form two sides of a right triangle, so that the top or the breech face is farther from the hinge pin, in straight-line distance, than the bottom. In a side-by-side gun there’s an additional advantage in that a top fastener is a bit more efficient in overcoming the effects of barrel flip-for the gun, if not for the shooter. With a top fastener, the barrels still flip downward on firing, but the action bar flexes less, and the fastener keeps the top of the barrels from pulling away from the breech face."

"The most interesting of the American top fasteners is the L.C. Smith’s patented by Alexander Brown in 1883. Where all the others used either Greener’s transverse bolt, some sort of flat bolt or hook on the front end of the top lever, or both, Brown designed his bolt as a steel cylinder that turns on a horizontal axis. A slot filed into the cylinder forms the actual hook, which fits into a slot in the rib extension. The cylinder also engages a lip at the rear of the extension as a secondary bite. L.C. Smith described this arrangement as a double cross-bolt, although double rotary bolt would be more accurate."

They also discussed some disadvantages of the rotary bolt, with examples of actions shot loose with time (and magnum loads), but did agree that the top fastener mechanism "…makes excellent sense."

We’ll allow that the Smith advertising slogan used on c. 1900s ads, letterheads, and mailers "The only gun in the world guaranteed to shoot any NITRO POWDER made and NOT GET LOOSE"might be just a bit of marketing hyperbole, but the strength of the rotary bolt locking mechanism is without question.

COPYRIGHT

L.C. Smith Collectors

Association 2015

Updated 02/18/2015

|